Product Description

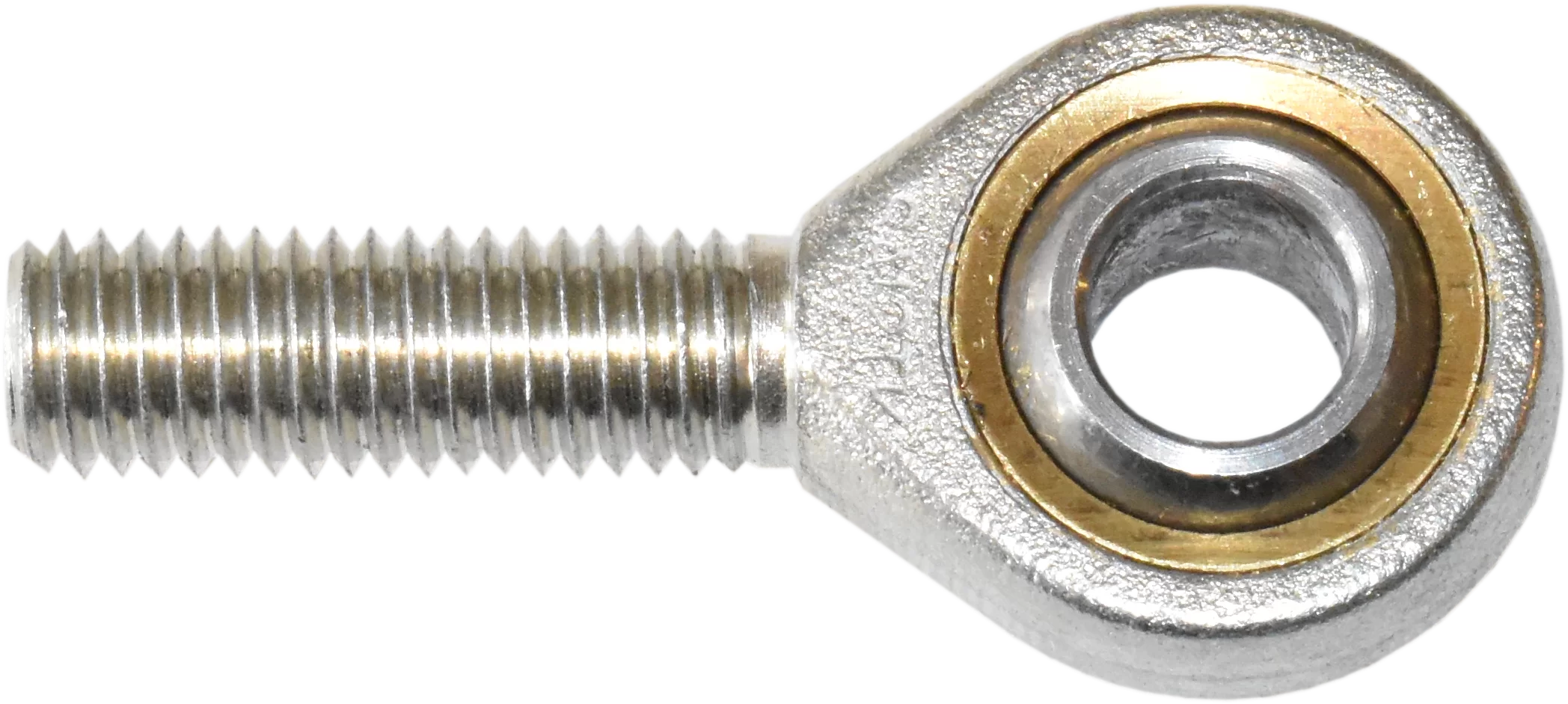

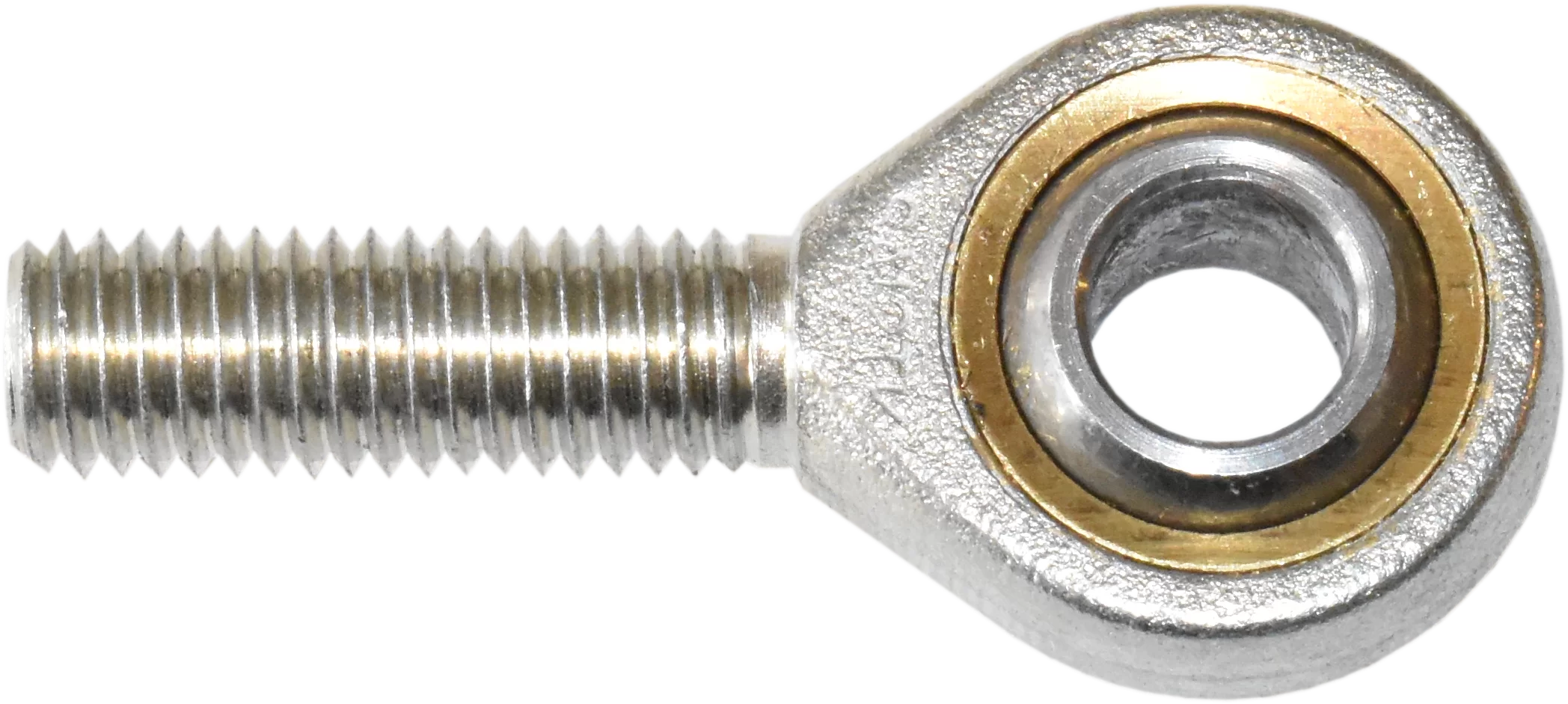

Engineering Hydraulic Cylinder Radial Spherical Plain Bearings

Outer ring with single split in axial direction

Lubrication grooves and holes in the outer and inner rings of type ES.

Outer ring of type-2rs with 2 seals.

Both outer and inner are properly phosphorlylate-treated.

Sliding surfaces: steel/steel

| Spherical plain bearings with fitting crack GE???E | Steel/ Steel |

Outer ring of carbon chromium steel, fractured, hardened and phosphated, sliding surface treated with MoS2. It has characteristies of wear-resistance, wear-corrosion and self-aligning, suitable for heavy radial loads and any direction lower axial loads mechanism. |

| Spherical plain bearings with fitting crack GE???ES | Steel/ Steel |

Same as series GE???E, but can be relubricated via annular grooves and lubrication holes in both rings. |

| Spherical plain bearings with fitting crack GE???ES-2RS | Steel/ Steel |

Same as series GE???ES, but with 2 seals at both sides, special for bearing arrangement where separate seals do not provide adequate protection. |

Packing & delivery

Our Factory&Company

Q: Are you trading company or manufacturer?

A :Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

Q: How to ensure the quality?

A:We produce as per the confirmed technology or drawings for each customer. And our factory has a strict quality control system.If the products is damaged due to our reasons,we assume full responsibilities.

Q: What is your delivery time?

A :Generally 10-25 days after order. It depends on the quantity

Q: Do you produce samples? Is it free or extra?

A :For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard and Non Standard |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Rod End Bearings to Complex Motion in Industrial Machinery

Rod end bearings play a significant role in ensuring the proper functioning of industrial machinery with complex motion. Here’s how they contribute:

1. Articulation and Pivoting:

Industrial machinery often requires components that can pivot and articulate in multiple directions. Rod end bearings provide a flexible connection point, allowing for a wide range of motion. They are commonly used in applications like robotic arms, conveyor systems, and material handling equipment, where precise movement and adaptability are essential.

2. Load Transmission:

Industrial machinery frequently deals with heavy loads and dynamic forces. Rod end bearings efficiently transmit these loads from moving components to stationary structures. Whether it’s the linear movement of a press or the tilting motion of a heavy-duty crane, rod end bearings enable the smooth transfer of forces, reducing wear and tear on the machinery.

3. Misalignment Compensation:

Machinery parts can become misaligned due to manufacturing tolerances, wear, or other factors. Rod end bearings excel at compensating for misalignments, ensuring that moving parts remain connected and operational. This capability is crucial in applications with variable alignment requirements, such as industrial automation systems and assembly line equipment.

4. Precision and Control:

Many industrial processes demand precision and control over motion. Rod end bearings help achieve this by providing a reliable connection point that can be adjusted and fine-tuned. This precision is essential in applications like CNC machinery, where the accuracy of tool movement directly impacts the quality of the final product.

5. Corrosion Resistance:

Industrial machinery operates in diverse environments, some of which may expose components to moisture and corrosive substances. Rod end bearings are available in various materials, including stainless steel, which offers excellent corrosion resistance. This ensures the bearings’ longevity and reliability, even in challenging conditions.

Overall, rod end bearings contribute to the efficient and reliable operation of industrial machinery with complex motion requirements. Their ability to accommodate articulation, handle heavy loads, compensate for misalignment, provide precision, and resist corrosion makes them invaluable components in various industrial applications.

Contribution of Rod End Bearings to Smooth Movement in Automotive Control Systems

Rod end bearings play a crucial role in ensuring the smooth movement of control systems in various automotive applications. Here’s how they contribute:

1. Steering Systems:

Rod end bearings are used in steering linkages and tie rod ends. They provide the necessary articulation and pivoting to allow the front wheels to turn smoothly, enabling precise steering control. The low friction and high load-bearing capacity of rod end bearings contribute to responsive and accurate steering in both manual and power steering systems.

2. Suspension Systems:

In suspension systems, rod end bearings are used in components like control arms and stabilizer links. They allow for controlled movement of the suspension, ensuring that the vehicle’s wheels maintain optimal contact with the road surface. This contributes to a smoother and more comfortable ride, improved handling, and better traction, especially when driving over uneven or bumpy terrain.

3. Throttle and Accelerator Linkages:

Rod end bearings are employed in throttle and accelerator linkages, where they assist in transmitting pedal inputs to the engine’s throttle body. The smooth articulation provided by rod end bearings ensures that drivers can easily modulate engine power, contributing to smooth acceleration and deceleration.

4. Gear Shift Linkages:

In manual transmissions, rod end bearings are used in gear shift linkages. They enable precise and smooth gear changes by allowing for the controlled movement of the shift lever. This ensures that gears engage smoothly, reducing drivetrain shock and vibration.

5. Convertible Roof Mechanisms:

In convertible cars, rod end bearings are used in the mechanisms that operate the folding and unfolding of the convertible roof. The smooth articulation of rod end bearings contributes to the seamless transition between open and closed roof positions, enhancing the overall driving experience.

Overall, rod end bearings are integral components in automotive control systems, ensuring the smooth and precise operation of various critical functions, including steering, suspension, throttle control, gear shifting, and convertible roof movement.

Design Principles and Functions of Rod End Bearings

Rod end bearings, also known as heim joints or rose joints, are essential components in various mechanical applications, where articulation and precise control of movement are required. These bearings are designed with specific principles and functions in mind:

Design Principles:

Rod end bearings consist of a spherical plain bearing, also known as a spherical plain bushing, within a housing. The design principles are as follows:

- Spherical Plain Bearing: The heart of a rod end bearing is a spherical plain bearing. This bearing allows the inner ring to tilt and rotate in multiple directions. It consists of an inner and outer ring with a sliding layer of material in between, often made from self-lubricating materials.

- Housing: The spherical plain bearing is housed within a protective casing, typically made of metal or other durable materials. The housing provides structural support and retains the bearing components.

- Threaded Shank: The outer part of the housing is often shaped as a threaded shank, allowing for easy attachment to various mechanical components, such as linkages or control arms.

- Lubrication Fittings: Many rod end bearings have provisions for lubrication fittings to ensure smooth articulation and reduce friction.

Functions:

Rod end bearings serve several crucial functions in mechanical systems:

- Articulation: Rod end bearings provide articulation, enabling components to pivot, swivel, and move in multiple directions. This function is vital in applications requiring flexibility and control over movement.

- Angular Misalignment Compensation: They can compensate for both static and dynamic angular misalignment. This is particularly useful in situations where components may not align perfectly due to varying factors like vibration or assembly tolerances.

- Load Transmission: Rod end bearings can transmit static and dynamic loads, making them suitable for applications involving force or load transfer. They are used in machinery and equipment where precise control of loads is essential.

- Precision Movement: These bearings provide precise control and movement, making them suitable for applications where accurate positioning of mechanical components is critical. This includes industries like aerospace and robotics.

- Corrosion Resistance: Many rod end bearings are designed with corrosion-resistant materials or coatings, making them suitable for use in harsh environments, such as marine and industrial settings.

- Durability: Rod end bearings are engineered for durability, allowing them to withstand challenging conditions and heavy-duty use. This ensures their reliability and longevity in demanding applications.

- Versatility: Rod end bearings are versatile components used across various industries, including automotive, aerospace, industrial machinery, and marine applications. Their adaptability and reliability make them valuable to engineers and designers.

These design principles and functions of rod end bearings make them indispensable in a wide range of mechanical systems where articulation, load-bearing capacity, and precise control are required.

editor by CX 2024-05-09

China high quality Top Quality Ball Joint Rod End Bearings carrier bearing

Product Description

Ball Joint rod end is as spare parts which widely required by many models of auto cars. We supply this series Rod End to customers according to clients’ drawings or samples. Customized and OEM orders are warmly welcomed!

Model No.: PCYML6T, PCYML8T, PCYML10T, PCYML12T

BALL

- 52100 Bearing Steel

- Heat Treated

- Hard Chrome Plated

- Precision Ground

BODY

- Chromoly Steel

- Heat Treated

- Black Oxide Coated

- PTFE Lined (PCM-T)

| Part Number | Boundary Dimensions (inch) |

Thread UNF-3A | Misalign Angle a° |

Ult. Radial Static Load ( lbs.) |

Approx. Bearing Weight (lbs) |

||||||

| Left Hand | Right Hand | B +0.0015 -0.0005 |

W ±0.005 |

A ±0.015 |

D Ref. | Ball Dia. Ref. | C +0.062 -0.031 |

||||

| PCYML6T | PCYMR6T | 0.375 | 0.875 | 2.125 | 1.125 | 0.812 | 1.375 | 3/8-24 | 55 | 11050 | 0.14 |

| PCYML7T | PCYMR7T | 0.4375 | 1 | 2.438 | 1.312 | 0.937 | 1.5 | 7/16-20 | 58 | 14449 | 0.22 |

| PCYML8-10T | PCYMR8-10T | 0.5 | 1.25 | 2.875 | 1.75 | 1.125 | 1.75 | 5/8-18 | 65 | 24158 | 0.44 |

| PCYML8T | PCYMR8T | 0.5 | 1.25 | 2.625 | 1.5 | 1.125 | 1.625 | 1/2-20 | 65 | 16240 | 0.33 |

| PCYML10-12T | PCYMR10-12T | 0.625 | 1.375 | 3.375 | 2 | 1.312 | 2 | 3/4-16 | 64 | 35710 | 0.68 |

| PCYML10T | PCYMR10T | 0.625 | 1.375 | 2.875 | 1.75 | 1.312 | 1.75 | 5/8-18 | 64 | 21219 | 0.51 |

| PCYML12T | PCYMR12T | 0.75 | 1.5 | 3.375 | 2 | 1.5 | 2 | 3/4-16 | 61 | 29127 | 0.79 |

Q1: Can I get a free sample?

A1: We provide samples free in freight collected. For special samples requirement, please contact us for more details.

Q2: How could I pay?

A2: We prefer T/T or L/C at sight. If you prefer other payment terms, please contact us freely.

Q3: What is your brand and packing way? Can you produce my brand and packing?

A3: Our brand is SGC and our own packing materials. We can make your brand. For more details, please contact us.

Q4: What is the delivery lead time?

A4: It depends on the order quantities. The mass production lead time is about 45-60 days after receipt of the deposit.

Q5: Are you manufacturer or trading company?

A5: We are manufacturer and exporter. We provide all kinds of OEM services for clients around the world.

Q6: Where is your main market?

A6: We export to the North America, Mexico, Australia, South-east Asia, Europe, U.A.E., Turkey, and other countries.

Our Services

1. Professional QC and QA team to make sure all products qualified before shipping.

2. Competitive price.

3 .Standard package to ensure the safe transportation.

4. Professional service.

Why choose us?

1. Production

Qualified production, competitive price, professional service.

2. Quality

All products are inspected 100% before shipment by relative testing equipments.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Element: | Single Row |

|---|---|

| Structure: | Rod End |

| Material: | Stainless Steel |

| Load Direction: | Radial Spherical Plain Bearing |

| Add Lubricant: | Self-lubricating |

| Outer Structure: | Outer Ring of Single-Slit |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improving Aircraft Functionality with Rod End Bearings

Rod end bearings play a critical role in enhancing the functionality and safety of various aircraft components, including control surfaces and landing gear. Here’s how:

Aircraft Control Surfaces:

Rod end bearings are commonly used in aircraft control systems to connect control surfaces, such as ailerons, elevators, and rudders, to control cables or rods. These bearings provide several key benefits:

- Articulation: Rod end bearings offer articulation capabilities, allowing control surfaces to move smoothly and precisely. This flexibility is essential for pilots to control the aircraft’s attitude, roll, pitch, and yaw.

- Misalignment Compensation: Aircraft structures experience various forces and vibrations during flight. Rod end bearings accommodate misalignment, ensuring that control systems remain effective even under dynamic conditions.

- Durability: Aircraft operate in challenging environments, and rod end bearings are designed to withstand extreme temperatures, vibrations, and mechanical stress. Their robust construction contributes to the longevity and reliability of control systems.

- Weight Savings: Aircraft design prioritizes weight reduction. Rod end bearings, typically made from lightweight materials like high-strength alloys or composites, help minimize the overall weight of the aircraft.

Landing Gear:

Rod end bearings are also utilized in landing gear systems, which are critical for safe takeoffs, landings, and ground operations. Their contributions include:

- Shock Absorption: Landing gear components, including rod end bearings, play a role in shock absorption during landing, reducing the impact forces transmitted to the aircraft’s structure and passengers.

- Articulation for Retraction and Extension: Rod end bearings enable the controlled movement of landing gear components, allowing for smooth retraction and extension. This is crucial for aerodynamic efficiency and safety.

- Structural Integrity: Rod end bearings help maintain the structural integrity of the landing gear assembly, ensuring that it can support the aircraft’s weight during ground operations.

Overall, rod end bearings in aircraft applications contribute to the precise control, safety, and structural reliability necessary for aviation. Their ability to handle articulation, misalignment, and challenging operating conditions makes them indispensable components in the aerospace industry.

Signs of Wear or Damage in Rod End Bearings and Replacement Guidelines

Rod end bearings are critical components in various mechanical systems, and it’s essential to monitor them for signs of wear or damage. Here are common indicators and guidelines for replacement:

1. Excessive Play or Looseness: If you notice excessive play or looseness in the rod end bearing, it’s a clear sign of wear. This can result in imprecise control and reduced system performance, so replacement is recommended.

2. Unusual Noises: Unusual noises such as knocking, clicking, or squeaking during movement are often indicative of rod end bearing issues. These noises can be a result of worn bearing surfaces or damaged components. Address the problem promptly to prevent further damage.

3. Corrosion or Rust: Exposure to moisture or harsh environmental conditions can lead to corrosion and rust on rod end bearings. Corroded bearings may not move smoothly, impacting system operation. If you observe significant corrosion, consider replacement.

4. Visible Damage: Any visible damage, such as cracks, dents, or deformation of the bearing’s body or components, should be taken seriously. Damaged rod end bearings can fail unexpectedly, leading to safety risks and system malfunctions. Replace them if damage is detected.

5. Reduced Range of Motion: If the rod end bearing restricts the range of motion or does not articulate smoothly, it may be worn or damaged. This can affect the performance of the associated system. Replacement is advisable to restore proper functionality.

6. Increased Friction: A sudden increase in friction during movement can indicate a lack of lubrication, contamination, or damage to the bearing surfaces. Re-greasing and cleaning may help, but if the issue persists, consider replacing the bearing.

7. Maintenance Intervals: Depending on the application, rod end bearings may have recommended maintenance intervals. Follow these guidelines and inspect the bearings during routine maintenance. If wear or damage is detected, replace them as necessary.

8. Safety Concerns: In safety-critical applications, it’s vital to prioritize bearing replacement at the first sign of wear or damage. Failure to do so can result in accidents or system failures with serious consequences.

Regular inspection and maintenance of rod end bearings are essential to ensure the continued reliability and performance of mechanical systems. When any of the above signs are observed, it’s advisable to replace the bearings promptly to prevent further issues and potential safety risks.

Applications and Industries Using Rod End Bearings

Rod end bearings find application across various industries and serve multiple purposes due to their versatility and design. Common applications and sectors where rod end bearings are used include:

1. Automotive: Rod end bearings are utilized in vehicle suspension systems, steering linkages, and throttle linkages, contributing to precise control and smooth movement.

2. Aerospace: They play a crucial role in aircraft control systems, ensuring reliable and precise movement in critical flight control components.

3. Construction and Heavy Machinery: These bearings are used in heavy equipment like cranes, excavators, and loaders for precise positioning and movement in various parts of the machinery.

4. Manufacturing: In manufacturing machinery, rod end bearings are employed for automation and motion control applications, ensuring accurate and smooth movement in industrial processes.

5. Agricultural Equipment: Farm machinery, such as tractors and combines, use rod end bearings in steering systems, hydraulics, and other mechanical components.

6. Robotics: Rod end bearings are critical in robotic arms and automation systems, facilitating precise movement and control in manufacturing, medical, and other industries.

7. Marine and Offshore: They are used in marine applications, contributing to reliable control and movement in boat steering systems and offshore equipment.

8. Medical Equipment: In medical devices and equipment, rod end bearings ensure precise and smooth movement, making them essential in applications like surgical robots and diagnostic instruments.

9. Racing and Motorsports: Rod end bearings are used in high-performance vehicles for suspension and steering systems, where precise control is paramount.

10. Material Handling: Conveyor systems and material handling equipment benefit from rod end bearings, ensuring efficient movement and transport of goods.

11. Renewable Energy: They play a role in solar tracking systems and wind turbine applications, helping to adjust panel angles and rotor blades for optimal energy capture.

12. Rail and Transportation: In rail systems and transportation equipment, rod end bearings are employed in various components, including doors, brakes, and suspension systems.

13. Sports and Fitness Equipment: In gym equipment and sports machinery, they provide smooth and reliable motion in treadmills, exercise bikes, and more.

Rod end bearings are valued for their ability to provide reliable and precise movement in a wide range of applications, contributing to the efficiency and safety of various industries.

editor by CX 2024-04-24

China Standard High Quality Combination Rod Ends Spherical Plain Bearings with Hot selling

Product Description

High Quality Combination Rod Ends Spherical Plain Bearings

Product Information:

Packing & delivery

Our Factory&Company

Q: Are you trading company or manufacturer?

A :Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

Q: How to ensure the quality?

A:We produce as per the confirmed technology or drawings for each customer. And our factory has a strict quality control system.If the products is damaged due to our reasons,we assume full responsibilities.

Q: What is your delivery time?

A :Generally 10-25 days after order. It depends on the quantity

Q: Do you produce samples? Is it free or extra?

A :For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard and Non Standard |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Improving Aircraft Functionality with Rod End Bearings

Rod end bearings play a critical role in enhancing the functionality and safety of various aircraft components, including control surfaces and landing gear. Here’s how:

Aircraft Control Surfaces:

Rod end bearings are commonly used in aircraft control systems to connect control surfaces, such as ailerons, elevators, and rudders, to control cables or rods. These bearings provide several key benefits:

- Articulation: Rod end bearings offer articulation capabilities, allowing control surfaces to move smoothly and precisely. This flexibility is essential for pilots to control the aircraft’s attitude, roll, pitch, and yaw.

- Misalignment Compensation: Aircraft structures experience various forces and vibrations during flight. Rod end bearings accommodate misalignment, ensuring that control systems remain effective even under dynamic conditions.

- Durability: Aircraft operate in challenging environments, and rod end bearings are designed to withstand extreme temperatures, vibrations, and mechanical stress. Their robust construction contributes to the longevity and reliability of control systems.

- Weight Savings: Aircraft design prioritizes weight reduction. Rod end bearings, typically made from lightweight materials like high-strength alloys or composites, help minimize the overall weight of the aircraft.

Landing Gear:

Rod end bearings are also utilized in landing gear systems, which are critical for safe takeoffs, landings, and ground operations. Their contributions include:

- Shock Absorption: Landing gear components, including rod end bearings, play a role in shock absorption during landing, reducing the impact forces transmitted to the aircraft’s structure and passengers.

- Articulation for Retraction and Extension: Rod end bearings enable the controlled movement of landing gear components, allowing for smooth retraction and extension. This is crucial for aerodynamic efficiency and safety.

- Structural Integrity: Rod end bearings help maintain the structural integrity of the landing gear assembly, ensuring that it can support the aircraft’s weight during ground operations.

Overall, rod end bearings in aircraft applications contribute to the precise control, safety, and structural reliability necessary for aviation. Their ability to handle articulation, misalignment, and challenging operating conditions makes them indispensable components in the aerospace industry.

Contribution of Rod End Bearings to Smooth Movement in Automotive Control Systems

Rod end bearings play a crucial role in ensuring the smooth movement of control systems in various automotive applications. Here’s how they contribute:

1. Steering Systems:

Rod end bearings are used in steering linkages and tie rod ends. They provide the necessary articulation and pivoting to allow the front wheels to turn smoothly, enabling precise steering control. The low friction and high load-bearing capacity of rod end bearings contribute to responsive and accurate steering in both manual and power steering systems.

2. Suspension Systems:

In suspension systems, rod end bearings are used in components like control arms and stabilizer links. They allow for controlled movement of the suspension, ensuring that the vehicle’s wheels maintain optimal contact with the road surface. This contributes to a smoother and more comfortable ride, improved handling, and better traction, especially when driving over uneven or bumpy terrain.

3. Throttle and Accelerator Linkages:

Rod end bearings are employed in throttle and accelerator linkages, where they assist in transmitting pedal inputs to the engine’s throttle body. The smooth articulation provided by rod end bearings ensures that drivers can easily modulate engine power, contributing to smooth acceleration and deceleration.

4. Gear Shift Linkages:

In manual transmissions, rod end bearings are used in gear shift linkages. They enable precise and smooth gear changes by allowing for the controlled movement of the shift lever. This ensures that gears engage smoothly, reducing drivetrain shock and vibration.

5. Convertible Roof Mechanisms:

In convertible cars, rod end bearings are used in the mechanisms that operate the folding and unfolding of the convertible roof. The smooth articulation of rod end bearings contributes to the seamless transition between open and closed roof positions, enhancing the overall driving experience.

Overall, rod end bearings are integral components in automotive control systems, ensuring the smooth and precise operation of various critical functions, including steering, suspension, throttle control, gear shifting, and convertible roof movement.

Factors to Consider When Selecting a Rod End Bearing for a Specific Application

Choosing the right rod end bearing for a specific application is crucial to ensure optimal performance and longevity. Several factors should be taken into account during the selection process:

1. Load Capacity: Consider the magnitude and type of loads the bearing will need to support. Determine whether it will experience radial, axial, or a combination of loads. Select a rod end bearing with the appropriate load capacity rating to handle these loads.

2. Misalignment: Evaluate the degree of angular misalignment that may occur in the application. Some rod end bearings are designed to compensate for misalignment better than others. Choose a bearing that can accommodate the expected misalignment without compromising performance.

3. Environment: Take into account the operating environment. Consider factors like temperature, humidity, chemical exposure, and the presence of contaminants. Select a rod end bearing with suitable materials and protective features to withstand these conditions.

4. Lubrication: Proper lubrication is essential for the longevity and smooth operation of rod end bearings. Determine the lubrication method and frequency required for the application. Some rod end bearings come with built-in lubrication provisions or self-lubricating materials.

5. Thread Type and Size: The threaded shank of the rod end bearing should match the components it connects to. Consider the thread size and type (e.g., right-hand or left-hand threads) to ensure compatibility with your application.

6. Corrosion Resistance: If the application is in a corrosive environment, select a rod end bearing with corrosion-resistant materials or coatings. This is especially important in marine, chemical, or industrial settings.

7. Size and Weight Constraints: Ensure that the chosen rod end bearing fits within the space and weight limitations of the application. Measure the available space and consider weight restrictions when making your selection.

8. Operating Speed: Take into account the rotational or oscillatory speed of the bearing. Some rod end bearings are designed for high-speed applications, while others are better suited for low-speed or static applications.

9. Regulatory Compliance: In some industries, specific standards or regulations may apply to components like rod end bearings. Ensure that the selected bearing complies with any relevant industry standards or requirements.

10. Budget Constraints: While quality is essential, consider your budget constraints. Different rod end bearings come with varying price points. Choose a bearing that provides the necessary performance without exceeding your budget.

By carefully considering these factors, you can select the most suitable rod end bearing for your specific application, ensuring reliable and efficient operation.

editor by CX 2024-03-23

China Original single row timken tapered roller bearings 32016 bearing with high quality manufacturer

Type: Roller, CZPT tapered roller bearing

Composition: Taper

Relevant Industries: Lodges, Garment Outlets, Creating Substance Shops, Producing Plant, Equipment Restore Outlets, Food & Beverage Factory, Farms, Restaurant, House Use, Retail, Food Store, Printing Stores, Construction works , Power & Mining, Food & Beverage Stores, Other, Marketing Business

Product Quantity: 32016 bearing

Precision Ranking: P2,P4, LJKY-III 20A LJKY-III 30A LJKY-III 50A LJKY-III 80A 380v 3 3 period torque motor velocity controller for movie blowing machine P5,P6,P0

Seals Variety: Open

Amount of Row: one row

Material: stainless metal, Chrome Metal

Lubrication: Oil Grease

Vibration: V1 V2 V3 V4

Clearance: C2 C0 C3 C4 C5

Cage: Steel Cage.copper Cage.nylon Cage

Deal: Unique Package deal

Sample: totally free

Shipping and delivery Time: regular Inside of 2 days

Design: 32016 bearing

Packaging Details: For CZPT taper roller bearing 32016 packaging1,.barreled deal+outer carton+pallets 2. solitary box+outer carton+pallets 3. tube package+center box+outer carton+pallets 4. In accordance to your need

Port: HangZhou/ZheJiang /HangZhou

Solution Information Product Data Unique single row CZPT tapered roller bearings 32016 bearing with substantial good quality

| Relevant Industries | Hotels,Garment Shops,Building Material Retailers,Manufacturing Plant,Machinery Fix Shops,Meals & Beverage Manufacturing unit,Farms,Cafe,House Use,Retail,Foods Store,Printing Outlets,Development functions ,Energy & 150CM 200CM Disco Mirror Ball MotorDMX Management Stage Lighting Products -1 Rpm Weighty Responsibility Rotator Motor Mining,Meals & Beverage Shops,Advertising and marketing Firm |

| Model Variety | 32016 |

| Precision Score | P0,P6,P5,P4,P2 |

| Seals Variety | Open Z ZZ RS 2RS |

| Variety of Row | Solitary Row |

| Area of Origin | Japan |

| Substance | stainless steel, Chrome Steel |

| Lubrication | Oil Grease |

| Vibration | V1 V2 V3 V4 |

| Clearance | C2 C0 C3 C4 C5 |

| Cage | Steel Cage.copper Cage.nylon Cage |

| Package deal | Unique Package |

| Sample | totally free |

| Supply Time | standard Inside 2 times |

Adopted is our firm’s introduction, if required, pls make contact with me. Our business is found in HangZhou of ZheJiang Province, We can provide bearings as follows: 1. Deep Groove Ball Beaings2. Self-aligning Ball Bearings3. Spherical Roller Bearings4. Angular-speak to Ball Bearings5. Tapered Roller Bearingssix. Cylindrical Roller Bearings7. Thrust Ball Bearings8. Spherical Thrust Roller Bearings9. Insert Ball Bearings10. Monitor Roller Bearings11. Needle Bearings12. Articulated Bearings13. Combined Bearings14. Overall Eccentric Bearings15. Linear Movement Bearings…….

Relevant Goods CompanyInfo Organization Profile HangZhou CZPT Bearing Co., LTDis a huge provider of well-known brand name bearings. We are the agent of numerous popular brand names, these kinds of as: Germany LUK, American UBC, NSK/IKO/NTN/KOYO/THK/ASAHI/NMB produced of Japan, England RHP, Korean SAMICK/KG/DPI and Chinese HRB/ZWZ/LYC/TWB/TMB/TR. We can give Certification of Origin.

Second, NUTR 60110 Track Roller Bearing NUTR60110 we can give diverse varieties of bearings which includedeep grooveball bearings, cylindrical roller bearings, tapered roller bearings, self-aligning ball bearings, angular make contact with ball bearings, thrust ball bearings, thrust roller bearings, pillow block bearings, needle roller bearings, joint bearings,

radial spherical simple bearings,spherical ball joint bearing, rod conclude bearing.substantial-temperature resistant bearings, Stainless bearings, plastic bearings, ceramic bearings, cylindrical roller thrust bearing,adapter sleeve and linear bearings.

Solution Method Creation Approach

Certifications Certifications

Item Packaging Item Packaging

Shipment & Payment Our Advantages

Types of Ball Bearings

If you’re looking to purchase a new ball bearing, there are many different types available. Learn about Single-row designs, Ceramic hybrid bearings, and Self-aligning ball bearings. You can also choose from stainless steel or single-row designs. Then, read about the different types of materials available to you. You’ll have an easier time making a decision. After all, you won’t have to worry about maintaining your new ball bearing, since it will be maintained by your supplier.

Single-row designs

Ball bearings with a single-row design have a high load-carrying capacity. They are used in applications where high loads must be handled smoothly. A single-row design is a good choice when the material’s properties require high load-carrying capacity but limited axial load capability. Single-row designs use two bearings with similar design features, but they have different mounting methods. Single-row designs can be adjusted either against one another to accommodate axial loads.

The single-row design is suitable for high-speed applications, but also has some disadvantages. The contact angle a is the angle between the radial plane and contact line. The larger the angle, the higher the axial load carrying capacity of the bearing. Single-row angular contact ball bearings are suitable for higher axial forces. Single-row angular contact ball bearings have a single-row design and support high axial forces in one direction. Single-row ball bearings are available in both pressed steel and machined steel cages.

Angular contact ball bearings with a single row feature a cage made of fiber-glass reinforced polyamide 66. These are available in diameters up to 130 mm. Four-point angular contact ball bearings use brass, steel, or brass plate. They have good running properties and a low coefficient of linear expansion. Single-row designs are easy to mount and are widely available. Alternatively, they can be mounted with a universal match design, which allows them to be easily adjusted.

One-row angular contact ball bearings are generally not suitable for angular misalignments because they are unsuitable for compensation of angular misalignments. Misalignments cause internal forces in the bearing which reduce its radial load capacity and life expectancy. This type of bearing is not suitable for adjacent mounting as it increases the chances of misalignment. However, it is a suitable choice for applications where only one bearing is required per bearing position.

Ceramic hybrid bearings

While all-ceramic bearings are limited to very specialized applications, Si3N4-based hybrid bearings are finding use in a wide range of high-speed machines. Compared to steel, ceramics are less susceptible to centrifugal forces, which are directly proportional to the mass of the balls. Because Si3N4 replacement balls have a lower density than steel, these bearings reduce the stress placed on the outer race.

The benefits of hybrid bearings are clear: they allow for higher speeds and loads than full-ceramic bearings, and they require no lubrication. Because of their many benefits, many industrial equipment operators are switching to these innovative bearings. CBR is one company that specializes in ceramic hybrid bearings and can help you find the best product for your application. If you are thinking about purchasing ceramic bearings for your next machine, here are some things you need to know about them.

A ceramic ball bearing surface has an extremely low coefficient of friction, which is important for applications that require low friction and high speeds. Ceramic balls also have a higher hardness than steel balls, which increases their life. In addition to this, ceramic hybrid bearings have superior thermal properties, generating less heat even when spinning at high speeds. These properties make ceramic hybrid bearings an ideal choice for high-speed machinery, especially electric motors. They are also suitable for applications that operate under water.

A ceramic ball hybrid bearing is much less susceptible to temperature fluctuations and wear. Because they are essentially indestructible, ceramic balls do not generate wear particles from the adhesive wear. They can run at significantly higher speeds than steel balls. Ceramic balls are also more resistant to moisture. For this reason, grease is a recommended lubricant in most ceramic bearing applications. These lubricants offer superior protection against moisture and corrosion. Further, they are available in many types.

Self-aligning ball bearings

A self-aligning ball bearing is one type of self-aligning bearing. These bearings are recommended for use in flex shaft systems. Their self-aligning feature prevents them from misaligning when in use. They can be used in both single and multiple-joint systems. In addition to self-aligning ball bearings, these units also feature flex shafts.

These self-aligning ball bearings come in a variety of configurations, including cylindrical, round, tapered, and straight bore. Their inner ring is tapered to meet specific tolerances. They are suitable for operating temperatures ranging from -30°F to 120°F. Their wide range of applications allows them to be used in general machinery, precision instruments, and low noise motors. In addition, they are available in a variety of outside diameters, widths, and internal clearances.

Self-aligning ball bearings have two rows of balls and one common sphered raceway in the outer ring. This enables them to automatically compensate for angular misalignment, which may be caused by machining and assembly errors or deflections. Compared to spherical roller bearings, these self-aligning ball bearings generate less friction. They run cooler even at high speeds. Self-aligning ball bearings also offer free engineering support.

Self-aligning ball bearings are designed for difficult shaft alignment. They are double-row, self-retaining units, with cylindrical or tapered bores. These bearings are available in open and sealed designs, and can also be used in applications with misalignment. They are also available with an outer ring that rotates in relation to the inner ring. When it comes to shaft misalignment, self-aligning ball bearings are a great solution.

Stainless steel

Stainless steel is a metal that resists corrosion and is highly durable. Its corrosion-resistant and water-resistance properties make it a good choice for bearings in food and marine applications. Additionally, stainless steel has hygienic benefits. Here are some of the benefits of stainless steel ball bearings. Read on to learn more about these amazing bearings! We’ve included some of the most common uses for stainless steel.

Hardness is important in a ball bearing. Steel uses the Rockwell C scale to measure hardness. A grade 25 steel ball bearing is accurate to 25 millionths of an inch, while a grade five ceramic bearing is less than a half-inch round. Although roundness is important, it shouldn’t be overemphasized, as the bearing surfaces may not be as accurate as the grade of the metal. And remember, a higher price tag doesn’t mean a better product.

Stainless steel ball bearings are available in a variety of alloys. The alloys used in manufacturing a stainless steel ball bearing vary in hardness, strength, and ductility. Stainless steel ball bearings have high corrosion-resistance properties. Additionally, they have long lubrication lives. These benefits make them a popular choice for industrial applications. These bearings are easy to maintain, reduce replacement costs, and offer corrosion resistance.

The NTN Sentinel Series is a premium line of stainless steel bearings. The solid lube is NSF H1 registered and prevents grease from leaching into food. It is also corrosion-resistant and doesn’t need to be coated. The seals and slinger create a water-resistant barrier between the steel ball and the lubricant. It also adds safety and security to the bearing.

Plastic balls

For applications where noise and weight are major concerns, plastic balls are ideal. These non-magnetic balls are ideal for MRI X-ray machines and sensors. They are also easy to lubricate, and are non-magnetic. A polymer ball bearing is the lightest of all three types. This makes them a good choice for many industries. Read on to learn more. This article will introduce some of the advantages of plastic balls for ball bearings.

Although ceramic ball bearings are more durable and offer many advantages, they are more expensive than plastic. Fortunately, plastic ball bearings offer a cheaper alternative. These bearings feature all-plastic races and cages. Depending on the application, plastic balls can be used in applications involving chemicals. In these cases, plastic ball bearings are available with a C160 grade, which is safe for use in temperatures below 176 deg F.

Medical devices often require precision specialty balls, which are made of glass, stainless steel, and plastic. These bearings must meet stringent cleanliness requirements. To meet the most stringent requirements, they must undergo ultrasonic cleaning. These bearings are available in plastic raceways, and are also available with glass or stainless steel balls. Polyethylene balls are lightweight and can be used in a variety of applications. They can be ordered in different sizes and tolerances to meet specific requirements.

Plastic balls for ball bearings are often mounted into other parts, such as plastic wheels, pulleys, and housings. They can be seamlessly integrated into other parts of a machine, which reduces assembly time and improves affordability. One important advantage of plastic bearings is that they are rust-resistant. As such, they can be used in harsh environments without causing any damage. If a piece of equipment is exposed to extreme temperatures, polymers are the ideal choice.

editor by czh 2023-02-20

China High Quality Nj 315 Skf Cylindrical Roller Bearings 42315 75x160x37mm For Machinery with Great quality

Kind: Roller

Structure: cylindrical

Applicable Industries: Constructing Content Shops, Manufacturing Plant, Machinery Mend Stores, Farms, House Use, Retail, Printing Shops, Design works , Strength & Mining, Advertising Organization, Machine

Model Amount: NJ315

Precision Score: P0, P6

Seals Variety: Open up, BDZ38-1J DAC38680026 38X68X26mm Auto Bearing Vehicle Wheel Hub Bearing Wheel Bearing DAC38680026 Open

Quantity of Row: Single row

Quantity of row: Single row

Materials: Chrome metal, bearing steel, iron

support: OEM Customized Solutions

lubribation: Oil

Vibration Amount Code: V1,V2,V3

Cage: Metal,Nylon,Brass

Package: Demands

Model: KONLON or Normal

Quality: P0, P6

Packaging Particulars: Packaging:1. Industrial packaging: 1pc/plastic bag + colour box +carton + pallet2. Industrial packaging:a). plastic tube + carton + palletb). plastic bag + kraft paper + carton + pallet3. In accordance to the requirement of client

Products Show Bearing Description

| Product Identify | Cylindrical Roller Bearing NJ315 42315 75x160x37mm |

| Material | Gcr15 |

| Color | Steel |

| Standard | GB-T |

| Grade | P0,P6, Ac servo motor value 67kw 50kw 45kw 37kw 30kw 20kw 15kw 12kw 11kw 10kw P5 |

| Brand | KONLON or Normal |

| Used | Car, Cranes, Bike, Equipment |

Great ValueThe most value-effective bearing

Quick SupplyRobust productiveness is quickly enough for shipping

Our Organization FactoryOur Factory WorkshopOur Workshop

WarehouseOur Warehouse

TeamOur Staff

Packing & Supply Packing Information :Customizable

Supply Details : 3-30 days

1. Bearing two. Bearing with Tube three. Box four. Carton 5. Wooden pallets 6. Comprehensive deal Our Certifications CertificationsCertifications

Consumer Image Client PhotoBuyer Image

Client PictureConsumer Image

Buyer PictureBuyer Photograph

FAQ Q: Are you trading firm or producer ?A: We are manufacturing facility.

Q: How lengthy is your supply time?A: Typically it is 5-ten days if the goods are in stock. or it is fifteen-30 days if the products are not in stock, it is according to quantity.

Q: Do you supply samples ? is it totally free or extra ?A: Yes, we could offer the sample for free charge but do not spend the value of freight.

Q: What is your conditions of payment ?A: Payment=1000USD, 30% T/T in progress ,balance before shippment.If you have another concern, 6312zz Manufacturing facility value Huge bearing Solitary row ball Bearing metal 60x130x31mm 6312rs deep groove ball bearings pls really feel cost-free to speak to us as beneath:

Industrial applications of casing

For rotating and sliding parts, bushings are an important part of the machine. Due to their anti-friction properties and load-carrying capacity, they are an important part of many different industrial processes. Bushings play a vital role in industries such as construction, mining, hydropower, agriculture, transportation, food processing and material handling. To learn more about the benefits of bushings, read on. You’ll be amazed how much they can help your business!

type

When comparing enclosure types, consider the material and how it will be used. Oilite bushings are made of porous material that draws lubricant into the liner and releases it when pressure is applied. These are manufactured using a sintered or powered metal process. Copper and tin are the most commonly used materials for making copper bushings, but there are other types of metal bushings as well.

Another popular type is the plain bearing. This type reduces friction between the rotating shaft and the stationary support element. This type provides support and load bearing while relying on soft metal or plastic for lubrication. Journal bearings are used to support the linear motion of the engine crankshaft in large turbines. They are usually babbitt or hydrodynamic with a liquid film lubricant between the two halves.

The oil-impregnated paper sleeve is made of high-quality kraft insulating paper. These bushings contain two layers of capacitor grading, with the innermost layer electrically connected to the mounting flange. These are mature processes and are widely used in different voltage levels. CZPT Electric (Group) Co., Ltd. provides UHV DC and AC oil-impregnated paper wall bushings for environmental control rooms.

Electrical bushings are used to transmit electricity. These can be transformers, circuit breakers, shunt reactors and power capacitors. The bushing can be built into the bushing or through the bushing. The conductors must be able to carry the rated current without overheating the adjacent insulation. A typical bushing design has a conductor made of copper or aluminum with insulation on all other sides. If the bushing is used in a circuit, the insulation needs to be high enough to prevent any leakage paths.

Voltage and current ratings of electrical bushings. Solid type electrical bushings typically have a center conductor and a porcelain or epoxy insulator. These bushings are used in small distribution transformers and large generator step-up transformers. Their test voltage is typically around 70 kV. Subsequent applications of this bushing may require a lower halfway release limit. However, this is a common type for many other applications.

application

Various industrial applications involve the use of casing. It is an excellent mechanical and chemical material with a wide range of properties. These compounds are also packaged according to national and international standards. Therefore, bushings are used in many different types of machines and equipment. This article will focus on the main industrial applications of casing. This article will also explain what a casing is and what it can do. For more information, click here. Casing application

Among other uses, bushing assemblies are used in aircraft and machinery. For example, a fuel tank of an aircraft may include baffle isolator 40 . The bushing assembly 16 serves as an interface to the fuel tank, allowing electrical current to flow. It can also be used to isolate one component from another. In some cases, bushing assemblies are used to provide a tight fit and reduce electrical resistance, which is important in circuits.

The benefits of casing go beyond reducing energy transmission. They reduce lubrication costs. If two metal parts are in direct contact, lubrication is required. Thus, the bushing reduces the need for lubrication. They also allow parts of the car to move freely. For example, rubber bushings may begin to deteriorate due to high internal temperatures or cold weather. Also, oil can affect their performance.

For example, bushing CTs in oil and gas circuit breakers are used as window current transformers. It consists of a toroidal core and secondary windings. The center conductor of the bushing acts as the single-turn primary of the BCT. By tapping the secondary winding, the ratio between primary and secondary can be changed. This information can be found on the asset nameplate.

Among other uses, bushings are used in diagnostic equipment. These components require precise positioning. Fortunately, air sleeves are perfect for this purpose. Their frictionless operation eliminates the possibility of misalignment. In addition, products based on porous media help minimize noise. A casing manufacturer can advise you on the best product for your equipment. Therefore, if you are looking for replacement bushings for your existing equipment, please feel free to contact Daikin.

Material

Dry ferrule cores were selected for study and examined under an Olympus polarizing microscope (BX51-P). Core slices showing layers of aluminum foil with a distance of approximately 2 cm between adjacent capacitor screens. The aluminum foil surface has a multi-layered structure with undulations due to shrinkage and crepe. Differences between the two types of foils are also revealed.

A typical metal bushing material consists of a high-strength metal backing and a solid lubricant. These materials have higher load-carrying capacity and low friction during operation. Additionally, they are precision machined to tight tolerances. They also offer better thermal conductivity and better fatigue resistance. The accuracy of the metal bushing is improved due to the re-machining process that takes place after the bearing is assembled. Additionally, metal bushing materials are more resistant to wear than plastic bushing materials.

Plastic bushings are relatively inexpensive and readily available off the shelf. Also, the price of custom plastic bushings is relatively low. However, they are not recommended for heavy duty applications. Plastics degrade under high loads and can damage mating parts. Also, if the plastic bushings are not manufactured accurately, they can become misaligned. These are just some of the reasons for choosing metal bushings over plastic.

A mechanically bonded bushing 40 is placed over the stabilizer bar and compressed into the outer sleeve/bracket assembly. The outer metal member includes slotted holes that compensate for the tolerance stacking between the first and second bushing assemblies. Pre-assembly allows the assembly plant to receive a complete assembly ready for vehicle assembly, rather than sub-assembly at the vehicle manufacturing plant.

cost

Control arm bushings are a major component of modern vehicle suspension systems. Damaged bushings can negatively affect the handling and performance of your car. Replacing bushings on a car can cost $200 to $500. While that’s pretty cheap for a handful of control bushings, replacing the entire suspension system could set you back over $1,200. Thankfully, if you want to repair or replace the bushing yourself, you can do it yourself for a fraction of the cost.

If you decide to replace the control arm bushing yourself, it’s best to shop around for the best price. Many auto parts stores offer cheaper bushings that you don’t have to spend a fortune on. Even if you don’t drive for years, rubber can degrade and create cracks in the material. These cracks can be as deep as three-eighths of an inch. This makes it dangerous to drive a car with damaged control arm bushings.

Hiring a mechanic might be a good idea if you don’t like doing the work yourself. You can save money and time by repairing the control arm yourself, but you may have to hire a mechanic to do the job. Replacing the front sway bar bushing alone can cost between $450 and $900. While these components are relatively inexpensive, you can replace them for a better-handling car.

In some cases, sizing the bushings is a more economical option, but if you want to replace your entire suspension system, it’s better to buy a brand new lower limit. You can even save labor by buying a replacement part fork with a good lower portion. In addition to improving your car’s handling and ride, new bushings will add to your car’s overall value. If you are not sure which parts you need, ask your mechanic for a quote.

While the cost of replacing control arm bushings is relatively low, it’s a good idea to compare quotes from multiple mechanics. By getting multiple quotes for the same repair, you can save as much as $50 to $100 on the total cost of your car. In addition to labor costs, parts and labor can vary, so shop around to find the mechanic best suited for your car. There’s no reason to settle for sub-par service when you can save $50 or more!

editor by czh 2023-02-18

China WSRY Original High quality Deep groove ball bearings 6216Z 6217RS 6218 2Z 6219 2RS 6220ZZ C3 Ball bearings with Chrome steel bearing bronze

Type: BALL

Structure: Deep Groove

Applicable Industries: Machinery Repair Shops, Construction works , Energy & Mining, Textile machine, Gear reducer, Engineering machinery, Household appliances, Transportation vehicles, Agricultural machinery, Construction machinery, Instruments and meters, Motors, Gearboxes, Food machinery, Printing machine

Bore Size: 0 – 400 mm

Model Number: 6216Z 6217RS 6218 2Z 6219 2RS 6220ZZ C3

Precision Rating: P0 P6 P5 P4 P2

Seals Type: OPEN Z 2Z ZZ RS 2RS

Number of Row: Single row

Brand: WSRY

Product name: Deep Grove Ball Bearing

Material: Chrome Steel GCR15

MOQ: 100pcs

Stock: Rich Stocks

Delivery Time: 3-5 Days

Package: Original Package

Cage: Steel Cage.copper Cage.nylon Cage

Service: OEM Customized Services

Samples: Avaliable

Packaging Details: 1. Universal Packing2. WSRY Packing3. Customized Packing4. Other original Packing

Port: HangZhou

Product Models

| 6000 Series | RS 2RS Z ZZ 2Z OPEN | ||||||

| 6200 Series | 6220 RS 2RS Z ZZ 2Z OPEN | ||||||

| 6300 Series | 6320 RS 2RS Z ZZ 2Z OPEN | ||||||

| 6400 Series | RS 2RS Z ZZ 2Z OPEN | ||||||

Industrial applications of casing

For rotating and sliding parts, bushings are an important part of the machine. Due to their anti-friction properties and load-carrying capacity, they are an important part of many different industrial processes. Bushings play a vital role in industries such as construction, mining, hydropower, agriculture, transportation, food processing and material handling. To learn more about the benefits of bushings, read on. You’ll be amazed how much they can help your business!

type

When comparing enclosure types, consider the material and how it will be used. Oilite bushings are made of porous material that draws lubricant into the liner and releases it when pressure is applied. These are manufactured using a sintered or powered metal process. Copper and tin are the most commonly used materials for making copper bushings, but there are other types of metal bushings as well.

Another popular type is the plain bearing. This type reduces friction between the rotating shaft and the stationary support element. This type provides support and load bearing while relying on soft metal or plastic for lubrication. Journal bearings are used to support the linear motion of the engine crankshaft in large turbines. They are usually babbitt or hydrodynamic with a liquid film lubricant between the two halves.

The oil-impregnated paper sleeve is made of high-quality kraft insulating paper. These bushings contain two layers of capacitor grading, with the innermost layer electrically connected to the mounting flange. These are mature processes and are widely used in different voltage levels. CZPT Electric (Group) Co., Ltd. provides UHV DC and AC oil-impregnated paper wall bushings for environmental control rooms.

Electrical bushings are used to transmit electricity. These can be transformers, circuit breakers, shunt reactors and power capacitors. The bushing can be built into the bushing or through the bushing. The conductors must be able to carry the rated current without overheating the adjacent insulation. A typical bushing design has a conductor made of copper or aluminum with insulation on all other sides. If the bushing is used in a circuit, the insulation needs to be high enough to prevent any leakage paths.

Voltage and current ratings of electrical bushings. Solid type electrical bushings typically have a center conductor and a porcelain or epoxy insulator. These bushings are used in small distribution transformers and large generator step-up transformers. Their test voltage is typically around 70 kV. Subsequent applications of this bushing may require a lower halfway release limit. However, this is a common type for many other applications.

application

Various industrial applications involve the use of casing. It is an excellent mechanical and chemical material with a wide range of properties. These compounds are also packaged according to national and international standards. Therefore, bushings are used in many different types of machines and equipment. This article will focus on the main industrial applications of casing. This article will also explain what a casing is and what it can do. For more information, click here. Casing application

Among other uses, bushing assemblies are used in aircraft and machinery. For example, a fuel tank of an aircraft may include baffle isolator 40 . The bushing assembly 16 serves as an interface to the fuel tank, allowing electrical current to flow. It can also be used to isolate one component from another. In some cases, bushing assemblies are used to provide a tight fit and reduce electrical resistance, which is important in circuits.

The benefits of casing go beyond reducing energy transmission. They reduce lubrication costs. If two metal parts are in direct contact, lubrication is required. Thus, the bushing reduces the need for lubrication. They also allow parts of the car to move freely. For example, rubber bushings may begin to deteriorate due to high internal temperatures or cold weather. Also, oil can affect their performance.

For example, bushing CTs in oil and gas circuit breakers are used as window current transformers. It consists of a toroidal core and secondary windings. The center conductor of the bushing acts as the single-turn primary of the BCT. By tapping the secondary winding, the ratio between primary and secondary can be changed. This information can be found on the asset nameplate.

Among other uses, bushings are used in diagnostic equipment. These components require precise positioning. Fortunately, air sleeves are perfect for this purpose. Their frictionless operation eliminates the possibility of misalignment. In addition, products based on porous media help minimize noise. A casing manufacturer can advise you on the best product for your equipment. Therefore, if you are looking for replacement bushings for your existing equipment, please feel free to contact Daikin.

Material

Dry ferrule cores were selected for study and examined under an Olympus polarizing microscope (BX51-P). Core slices showing layers of aluminum foil with a distance of approximately 2 cm between adjacent capacitor screens. The aluminum foil surface has a multi-layered structure with undulations due to shrinkage and crepe. Differences between the two types of foils are also revealed.

A typical metal bushing material consists of a high-strength metal backing and a solid lubricant. These materials have higher load-carrying capacity and low friction during operation. Additionally, they are precision machined to tight tolerances. They also offer better thermal conductivity and better fatigue resistance. The accuracy of the metal bushing is improved due to the re-machining process that takes place after the bearing is assembled. Additionally, metal bushing materials are more resistant to wear than plastic bushing materials.

Plastic bushings are relatively inexpensive and readily available off the shelf. Also, the price of custom plastic bushings is relatively low. However, they are not recommended for heavy duty applications. Plastics degrade under high loads and can damage mating parts. Also, if the plastic bushings are not manufactured accurately, they can become misaligned. These are just some of the reasons for choosing metal bushings over plastic.

A mechanically bonded bushing 40 is placed over the stabilizer bar and compressed into the outer sleeve/bracket assembly. The outer metal member includes slotted holes that compensate for the tolerance stacking between the first and second bushing assemblies. Pre-assembly allows the assembly plant to receive a complete assembly ready for vehicle assembly, rather than sub-assembly at the vehicle manufacturing plant.

cost

Control arm bushings are a major component of modern vehicle suspension systems. Damaged bushings can negatively affect the handling and performance of your car. Replacing bushings on a car can cost $200 to $500. While that’s pretty cheap for a handful of control bushings, replacing the entire suspension system could set you back over $1,200. Thankfully, if you want to repair or replace the bushing yourself, you can do it yourself for a fraction of the cost.

If you decide to replace the control arm bushing yourself, it’s best to shop around for the best price. Many auto parts stores offer cheaper bushings that you don’t have to spend a fortune on. Even if you don’t drive for years, rubber can degrade and create cracks in the material. These cracks can be as deep as three-eighths of an inch. This makes it dangerous to drive a car with damaged control arm bushings.

Hiring a mechanic might be a good idea if you don’t like doing the work yourself. You can save money and time by repairing the control arm yourself, but you may have to hire a mechanic to do the job. Replacing the front sway bar bushing alone can cost between $450 and $900. While these components are relatively inexpensive, you can replace them for a better-handling car.

In some cases, sizing the bushings is a more economical option, but if you want to replace your entire suspension system, it’s better to buy a brand new lower limit. You can even save labor by buying a replacement part fork with a good lower portion. In addition to improving your car’s handling and ride, new bushings will add to your car’s overall value. If you are not sure which parts you need, ask your mechanic for a quote.

While the cost of replacing control arm bushings is relatively low, it’s a good idea to compare quotes from multiple mechanics. By getting multiple quotes for the same repair, you can save as much as $50 to $100 on the total cost of your car. In addition to labor costs, parts and labor can vary, so shop around to find the mechanic best suited for your car. There’s no reason to settle for sub-par service when you can save $50 or more!

editor by czh

China high quality Single Row Ball Slewing Bearings Turntable Bearings Without Teeth Kdmh. U. 0955.00.10 with Hot selling

Merchandise Description

CZPT is a professional company in slewing ring bearings considering that 1993. We can also design and make other normal and non-common ball slewing ring bearings, roller slewing bearings and precision slewing ring bearings as for each customer’s various complex requirements.

Slewing ring bearing is also referred to as slewing ring, slewing bearing, turntable bearing, and rotary bearing.

Slewing ring bearing is a bearing that CZPT to bear axial load, radial load and overturning torque. Below CZPT conditions, slewing ring bearings have their very own mounting holes, CZPT holes and seal holes, to fulfill the distinct wants of the numerous host operating under the a variety of situations

On the other hand, slewing ring bearing alone has attributes of compact construction, CZPT CZPT practical, easy to set up and preserving very easily.

Slewing Ring Bearings——Sorts:

1. 4 point get in touch with ball slewing ring bearings

2. double row ball 4 stage get in touch with slewing ring bearings(very same diameter ball different diameter ball)

3. CZPT roller slewing ring bearings

four. triple row cylindrical roller blended slewing ring bearings

5. ball roller combined slewing ring bearings

six. mild flanged slewing ring bearings

Slewing Ring Bearings——Specialized Info:

1. Content: 42CrMo, 50Mn

two. Precision: P0. P6. P5.

three. Exterior diameter: 200~9500mm

four. Cage/retainer: Nylon or aluminum

5. Gear type: non-geared, internal gear and external equipment, gear hardened

Slewing Ring Bearings——Applications:

Slewing ring bearings are extensively utilized in market and known as “the device joints”

Hereunder is the particular slewing bearing applications

1. Construction CZPT (e.g. cranes, excavators, loader, scraper)

2. Metallurgical CZPT (e.g. for metal plant)

3. Weighty CZPT equipments (e.g. mining equipment, concrete machinery)

4. Marine CZPT tools (e.g. vessel, port hoisting device, port oil transfer gear, onshore and offshore crane)

five. Mild CZPT equipments (e.g. paper equipment, plastic, rubber machine, weave device)

6. Wind electricity generator

seven. Armed forces goods (e.g. aerospace machinery)

8. Packing equipment

Slewing Ring Bearings——Packaging Specifics:

Step 1: Covered with the anti-rust oil

Action 2: wrapped with the plastic film

Step 3: Packed with Kraft paper and skilled belts

Phase 4: Set into wooden box to avoid the rust or the moist

Remark: Usually, plastic movie+ Kraft +belt+ wood box, but customized packing offered,

Our Rewards:

1. Great top quality and aggressive value

2. Trial buy recognized

three. ISO certified company

four. OEM and ODM approved

5. Production slewing ring bearings considering that 2000

LYHY Slewing bearing types:

How to Exchange a Bearing

If you want to select a bearing for a certain software, you should know a couple of fundamentals. This post will give you an overview of ball, angular speak to, and sliding-speak to bearings. You can select a bearing according to the application based mostly on the attributes of its content and preload. If you are not confident how to pick a bearing, consider experimenting with it. The next step is to recognize the Z-axis, which is the axes together which the bearing moves.

Z axis

When it will come to replacing your Z axis bearing, there are a number of things you should know. 1st, you need to have to make confident that the bearings are seated correctly. Then, you should check the pressure and rotation of every single a single. To guarantee that both bearings are similarly tensioned, you must flex the Core to the wanted angle. This will maintain the Z axis perpendicular to the perform surface area. To do this, initial eliminate the Z axis bearing from its housing and insert it into the Z axis motor plate. Following, insert the flanged bearing into the Z axis motor plate and secure it with two M5x8mm button head cap screws.

Make positive that the bearing plate and the Z Coupler portion are flush and have equivalent spacing. The spacing in between the two components is important, as as well considerably spacing will lead to the leadscrew to turn out to be tight. The screws must be extremely loose, with the exception of the kinds that interact the nylocks. Right after installing the bearing, the subsequent phase is to commence the Z axis. Once this is completed, you’ll be ready to transfer it around with a stepper.

Angular make contact with

Ball bearings are manufactured with angular contacts that outcome in an angle amongst the bearing’s races. Although the axial load moves in one route via the bearing, the radial load follows a curved route, tending to individual the races axially. In order to decrease this frictional impact, angular make contact with bearings are developed with the very same speak to angle on the inner and outer races. The get in touch with angle must be picked to match the relative proportions of the axial and radial masses. Usually, a larger contact angle supports a larger axial load, although reducing radial load.

Ball bearings are the most frequent variety of angular speak to bearings. Angular get in touch with ball bearings are used in a lot of apps, but their primary function is in the spindle of a device device. These bearings are ideal for large-velocity, precision rotation. Their radial load potential is proportional to the angular contact angle, so larger make contact with angles tend to enlarge with velocity. Angular speak to ball bearings are accessible in one and double-row configurations.

Angular contact ball bearings are a fantastic selection for purposes that include axial masses and sophisticated designs. These bearings have raceways on the interior and outer rings and mutual displacement together the axial axis. Their axial load bearing capacity boosts as the make contact with Angle a rises. Angular make contact with ball bearings can endure loads up to five instances their first bodyweight! For those who are new to bearings, there are several methods on-line focused to the matter.

Regardless of their complexity, angular contact ball bearings are very functional and can be employed in a extensive selection of purposes. Their angular contact enables them to withstand average radial and thrust loads. As opposed to some other bearings, angular contact ball bearings can be positioned in tandem to reduce friction. They also feature a preload system that eliminates excessive engage in even though the bearing is in use.

Angular get in touch with ball bearings are made with various lubricants and cage materials. Normal cages for angular speak to ball bearings correspond to Desk 1. Some are machined synthetic resins even though other individuals are molded polyamide. These cage resources are used to additional enhance the bearing’s axial load potential. Even more, angular make contact with ball bearings can stand up to substantial speeds and radial hundreds. In contrast to radial contact ball bearings, angular get in touch with ball bearings offer the best overall flexibility.

Ball bearings

Ball bearings are round buildings with two independent rings. The scaled-down ring is mounted on a shaft. The interior ring has a groove on the outer diameter that functions as a path for the balls. Equally the interior and outer ring surfaces are completed with extremely substantial precision and tolerance. The outer ring is the circular structure with the rolling components. These elements can just take many varieties. The inner and outer races are typically manufactured of metal or ceramic.

Silicon nitride ceramic balls have excellent corrosion resistance and lightweight, but are far more high-priced than aluminum oxide balls. They also show an insulating result and are self-lubricating. Silicon nitride is also appropriate for large-temperature environments. However, this sort of material has the disadvantage of putting on out swiftly and is susceptible to cracking and shattering, as is the situation with bearing steel and glass. It’s also less resistant to heat than aluminum oxide, so it truly is ideal to acquire aluminum nitride or ceramic ball bearings for purposes that are subjected to very high temperatures.

Yet another type of ball bearings is the thrust bearing. It has a unique style that accommodates forces in equally axial and radial instructions. It is also called a bidirectional bearing since its races are side-by-facet. Axial ball bearings use a aspect-by-facet style, and axial balls are employed when the loads are transmitted through the wheel. Even so, they have inadequate axial assist and are prone to separating in the course of large radial masses.

The basic idea guiding ball bearings is to decrease friction. By reducing friction, you may be able to transfer a lot more energy, have less erosion, and enhance the daily life of your device. With modern improvements in technologies, ball bearings can execute greater than at any time prior to. From iron to steel to plastics, the components utilized in bearings have enhanced drastically. Bearings could also include an electromagnetic subject. So, it really is greatest to choose the proper a single for your machine.

The existence expectancy of ball bearings depends on many factors, such as the running speed, lubrication, and temperature. A single million-rpm ball bearing can deal with in between a single and five million rotations. As lengthy as its surface area contact region is as tiny as attainable, it really is most likely to be serviceable for at minimum one million rotations. Nonetheless, the common lifespan of ball bearings depends on the application and operating situations. Thankfully, most bearings can take care of a million or far more rotations ahead of they start displaying symptoms of exhaustion.

Sliding-make contact with bearings

The basic basic principle driving sliding-make contact with bearings is that two surfaces move in make contact with with one another. This kind of bearing performs best in scenarios in which the surfaces are produced of dissimilar resources. For occasion, a metal shaft shouldn’t run in a bronze-lined bore, or vice versa. Instead, 1 factor should be tougher than the other, given that use would concentrate in that area. In addition, abrasive particles tend to power them selves into the softer surface area, causing a groove to dress in in that part.