Product Description

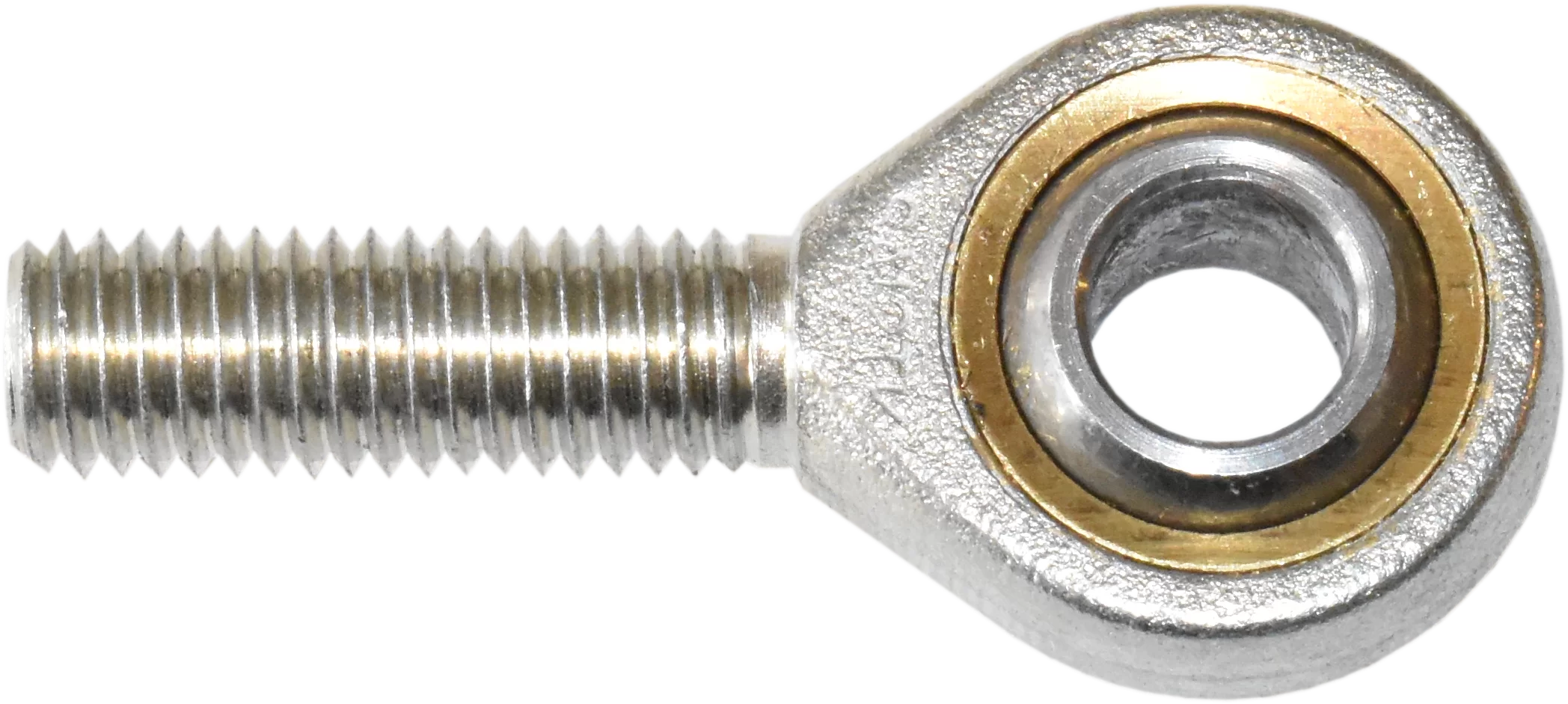

High Precision Combination rod ends Sperical Plain Bearings

Packing & delivery

Our Company

Q: Are you trading company or manufacturer?

A :Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

Q: How to ensure the quality?

A:We produce as per the confirmed technology or drawings for each customer. And our factory has a strict quality control system.If the products is damaged due to our reasons,we assume full responsibilities.

Q: What is your delivery time?

A :Generally 10-25 days after order. It depends on the quantity

Q: Do you produce samples? Is it free or extra?

A :For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard and Non Standard |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Differences Between Male and Female Threaded Rod End Bearings

Male and female threaded rod end bearings differ in their design and applications:

Male Threaded Rod End Bearings:

– Male rod end bearings have external threads on the shank or body of the bearing.

– They are typically used in applications where the bearing is mounted to a stationary component, and the threaded shank extends to connect with a mating part (e.g., a linkage or control arm).

– Male rod end bearings allow for easy adjustment or fine-tuning of the connection.

– These bearings are suitable for applications requiring controlled movement or positioning, where the bearing’s external threads facilitate precise adjustments.

Female Threaded Rod End Bearings:

– Female rod end bearings have an internal (female) threaded bore inside the housing.

– They are used when a bolt, stud, or shaft with external threads needs to be connected to the bearing’s housing.

– Female rod end bearings are often employed in applications where the bearing needs to rotate around a fixed shaft or bolt, providing articulation and misalignment capabilities.

– These bearings allow for the attachment of a variety of external components, making them versatile for different applications.

The choice between male and female threaded rod end bearings depends on the specific requirements of the application, including whether the bearing needs to be attached to a stationary part or connected to an external threaded component and the level of adjustability and articulation needed.

Challenges and Solutions in Managing Load and Misalignment in Rod End Bearings

Rod end bearings often face challenges related to load capacity and misalignment in various applications. Here are the common challenges and solutions:

1. Radial and Axial Loads:

Challenge: Rod end bearings need to handle both radial and axial loads simultaneously in many applications.

Solution: Select rod end bearings with appropriate load ratings and materials to ensure they can withstand the expected loads. Also, proper maintenance and lubrication are essential for maximizing load-carrying capacity.

2. Misalignment:

Challenge: Misalignment can cause premature wear and reduced bearing lifespan.

Solution: Use self-aligning rod end bearings or incorporate spherical plain bearings to compensate for misalignment. Regular inspection and maintenance to correct any alignment issues are crucial.

3. Corrosion and Contaminants:

Challenge: Exposure to moisture, chemicals, and contaminants can lead to corrosion and damage.

Solution: Choose rod end bearings with suitable protective coatings or seals, such as PTFE liners or rubber boots, to prevent contaminants from entering. Stainless steel bearings offer enhanced corrosion resistance.

4. Lubrication:

Challenge: Inadequate lubrication can result in increased friction, overheating, and premature failure.

Solution: Follow the manufacturer’s lubrication recommendations and maintenance schedules. Proper lubrication ensures smooth operation and extends bearing life.

5. Shock and Impact Loads:

Challenge: Applications with frequent shock and impact loads can subject rod end bearings to excessive stress.

Solution: Choose rod end bearings with robust construction and materials to withstand shock loads. Regular inspections are necessary to detect early signs of damage.

By addressing these challenges with appropriate solutions, rod end bearings can perform optimally and provide long-lasting service in a wide range of applications.

Scenarios Requiring Articulation and Pivoting with Rod End Bearings

Rod end bearings are essential components in scenarios where articulation and pivoting are crucial. Here are some examples:

- Vehicle Suspension: Rod end bearings in a vehicle’s suspension system allow articulation of the wheels, ensuring a smooth and controlled ride, especially on uneven terrain.

- Aircraft Control Surfaces: In aviation, rod end bearings enable the pivoting of control surfaces like ailerons, elevators, and rudders, providing precise control over an aircraft’s movements.

- Robotic Arms: Rod end bearings facilitate the articulation and pivoting of robotic arms in manufacturing, assembly, and medical robotics, allowing for precise and flexible movement.

- Construction Equipment: Heavy machinery such as excavators and cranes rely on rod end bearings for articulation in booms, buckets, and other moving parts for effective operation.

- Marine Steering Systems: Rod end bearings play a vital role in boat steering systems, allowing articulation of the outboard motor or inboard-outboard drive unit.

- Agricultural Machinery: Tractors and combines use rod end bearings to articulate and pivot components in the steering and hydraulic systems for farming operations.

- Rail and Transportation: In rail systems, rod end bearings help with the articulation of train doors, ensuring safe and efficient passenger entry and exit.

- Conveyor Systems: In material handling, rod end bearings assist in the pivoting and articulation of conveyor belt rollers and other components for the smooth movement of goods.

- Sports Equipment: Fitness machines like elliptical trainers use rod end bearings to facilitate articulation in pedal arms, allowing users to exercise effectively.

These examples demonstrate the versatility and importance of rod end bearings in various industries where articulation and pivoting are essential for optimal performance and control.

editor by CX 2024-04-25